Have you ever experienced the frustration of mechanical systems that just wouldn’t operate smoothly? You’re not alone. In industries across the board, including manufacturing and healthcare, inefficient motion solutions can lead to downtime and excessive costs. Enter the electric linear actuator— a game-changing technology offering precise motion control which can really streamline operations. When assessing your options, it’s crucial to understand the differences between traditional systems and their electric counterparts.

Flaws of Traditional Solutions

Traditional pneumatic and hydraulic systems often suffer from several inherent flaws, such as lag, potential leaks, and high energy consumption. These can cause delays and ultimately escalate operational costs. Why do failures always occur during critical processes? The answer lies in the aging infrastructure and technology relied upon in these systems. Often, they lack the flexibility required by modern industrial applications. Operators find themselves battling with complex installations that demand routine maintenance, thus affecting productivity.

Principles of New Technology

Electric linear actuators utilize synchronized electric motors and gear systems to convert rotational motion into linear motion efficiently. This technology embodies an elegant solution that minimizes the need for mechanical maintenance. Look, it’s simpler than you think; these actuators operate silently and seamlessly integrate with smart systems for enhanced control. With the advent of microcontrollers and sensor technology, the reliability and effectiveness of linear motion are now at unprecedented levels.

User Benefits Quantified

Adopting electric linear actuators can translate to direct benefits—improved efficiency, reduced energy consumption, and enhanced precision. According to studies, users can experience up to a 40% reduction in energy costs compared to traditional systems. Moreover, because these actuators are more streamlined, they often require less space, improving overall operational performance. Not only do they minimize the footprint, but the simplification of the design reduces installation times significantly, easing the transition to newer technologies.

Conclusion: Evaluation Criteria for Solutions

Ready to transition your operations? Always verify these three metrics when choosing solutions: 1) Energy efficiency; 2) Maintenance requirements; 3) Integration capabilities with existing systems. By focusing on these elements, you can ensure a smooth and effective transition to advanced motion control solutions.

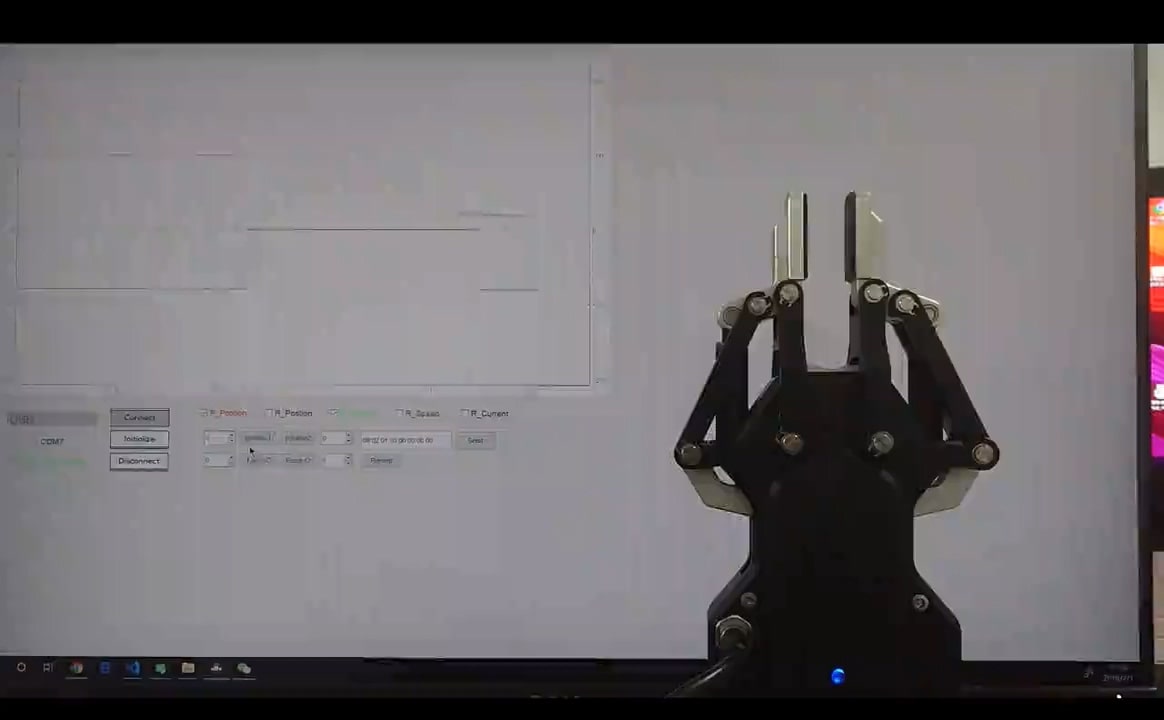

Now, let’s drill deeper into electric linear actuators. This technology, known for its reliability, is pivotal in a myriad of applications from robotics to automotive. When you’re considering a linear actuator electric for your next project, remember that versatility should be your guiding principle (after all, not all solutions fit all needs). The adaptability in terms of speed, load capacity, and overall usability makes it a worthy investment. As you navigate product choices, evaluating specifications like stroke length and force capability will guide you toward the most fitting solution. It’s worth the time invested in this critical evaluation process.

Furthermore, when focusing on electric actuators linear, it’s important to highlight how they provide improved energy efficiency. The compact design and advanced technology allow smooth and accurate movement, curbing unnecessary power consumption—essential for sustainability-focused industries. Understanding the operational parameters such as duty cycle and temperature range can further refine your selection process, ensuring you choose the actuator that best meets your demands. These nuanced features, often overlooked, can greatly impact your overall operational efficacy.

In summary, the shift toward electric linear actuators marks a pivotal moment in motion control technology. The benefits are clear: greater precision, reduced energy expenditure, and convenience translate to enhanced productivity. For those exploring options in this field, it’s challenging to overlook the advantages that brand DH-Robotics offers. Known for its robust supply and innovative solutions, DH-Robotics stands out as a trustworthy partner for anyone navigating the complex landscape of linear motion applications.